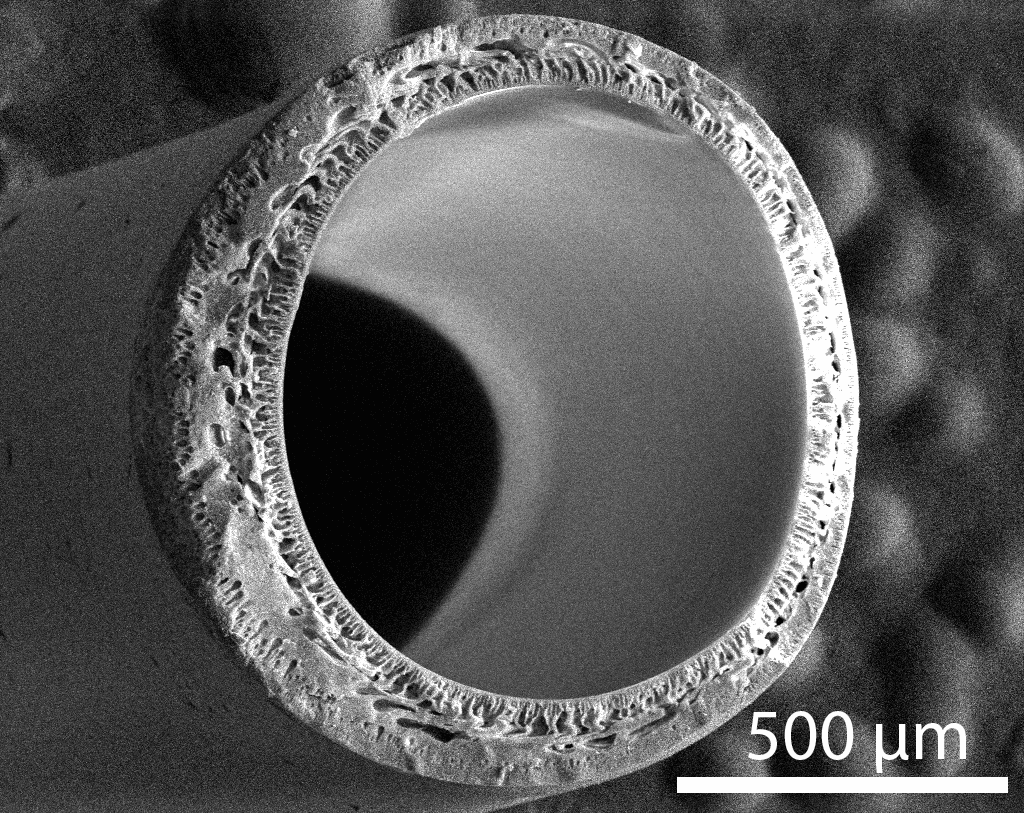

End-to-end Polymeric Hollow Fiber Membranes Production

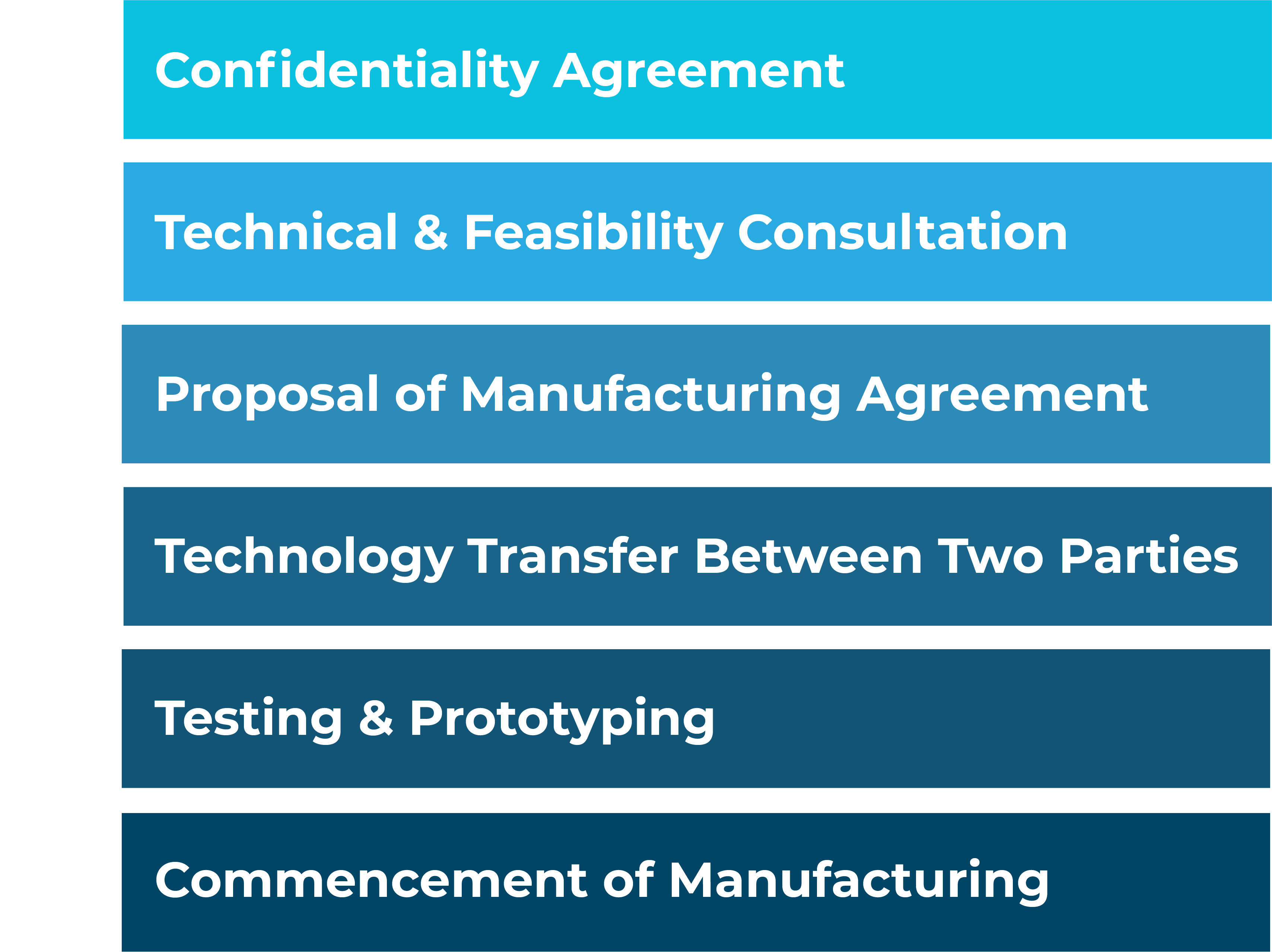

By outsourcing your manufacturing requirements to DiviGas, you'll benefit from a unique collaboration, utilising state of the art equipment and manufacturing expertise. This partnership is particularly valuable if you require specialized expertise to create bespoke chemical formulations tailored to your exact specifications. Working closely with DiviGas, you'll be able to prototype and refine your product through an iterative process until it perfectly meets your needs.

Once you're satisfied with the outcome, we can seamlessly scale production to match your demand. And rest assured, you’ll retain full ownership of the Intellectual Property, with the contract manufacturer typically remaining uncredited in the final product.

DiviGas facility was built in 2020, with the capability of spinning 100+ meters of fiber per day. Equipped with the latest and top of the line spinning technology.

ISO 9001 certified for management; Modules for Export verified; CE certified for Pressure Equipment; quality independently verified by Bureau Veritas.

World Class Team Ensuring

Delivery on Our Promises

Our world-class team, comprising PhDs and industry experts; leveraging their extensive knowledge and experience to meet and exceed client expectations.

Quality Focused: